These are the most commonly used structural steel sheets. Their quality, requirements for processing and properties are governed by regulation EN 10025-2. They are easy to machine and have excellent weldability. They are used for undemanding industrial or construction projects.

Need more information? Leave us your contact information and we will get back to you within 3 days.

Properties and use of ordinary structural steel sheets according to EN 10025-2

Classic sheets of non-alloy structural steel stand out for their strength, longevity and resistance to wear, which is determined by the production process. Hot rolling of sheets produces stronger and less brittle steel sheets. Their minimum yield strength starts at 235 MPa. Structural steel sheets, the technical requirements of which are specified by EN 10025-2, are suitable for all common welding processes and can be further surface-treated.

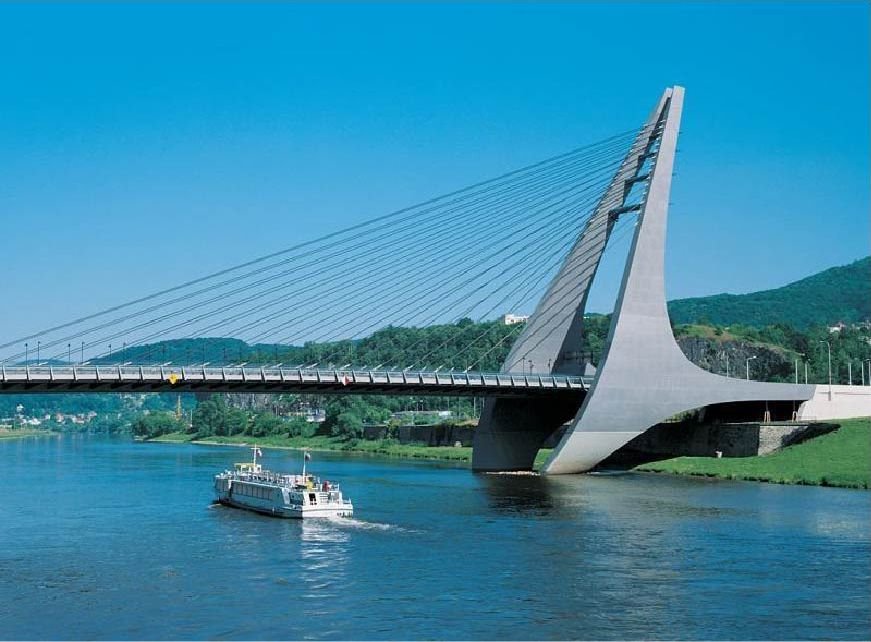

They are suitable for undemanding constructions such as bridges and footbridges, sports and industrial halls, parts of rail or motor vehicles or mining equipment. They can be used both in engineering and construction, as well as in other industries.

Choose from a wide range of sizes. We supply sheets in the following dimensions:

- length: max. 18,000 mm,

- width: 1000-3200mm,

- thickness: 5-100 mm,

- weight: max. 12,500 kg.

The stated dimensions are only approximate. The resulting appearance depends on the combination of individual parameters and material specification. Upon agreement, we are able to produce sheet metal up to a length of 21,000 mm and a thickness of 200 mm. For more information contact us.

Equivalent marking of steels

| EN 10025-2 | EN 10025+A1 | DIN 17100 | BS 4360 | NFA 35-501 |

|---|---|---|---|---|

| Quality S235JR(C) | S235JRG2(C) | RSt 37-2 | 40 B | E 24-2 |

| Quality S235J0(C) | S235J0(C) | St 37-3U | 40 C | E 24-3 |

| Quality S235J2(C) | S235J2G4(C) | St 37-3N | 40 D | E 24-4 |

| Quality S275JR(C) | S275JR(C) | St 44-2 | 43 B | E 28-2 |

| Quality S275J0(C) | S275J0(C) | St 44-3U | 43 C | E 28-3 |

| Quality S275J2(C) | S275J2G4(C) | St 44-3N | 43 D | E 28-4 |

| Quality S355JR(C) | S355JR(C) | – | 50 B | E 36-2 |

| Quality S355J0(C) | S355J0(C) | St 52-3U | 50 C | E 36-3 |

| Quality S355J2(C) | S355J2G4(C) | St 52-3N | 50 D | – |

| Quality S355K2(C) | S355K2G4(C) | – | 50 DD | -4 |

Basic characteristics of individual qualities

| Steel brand | Minimum yield strength ReH2) [MPa] |

Strength limit Rm [MPa] |

Minimum ductility [%] |

Minimum shock work KV [°C/J] |

CEV max.1) | Thickness 5) [mm] |

Thickness for variant (C) [mm] |

|---|---|---|---|---|---|---|---|

| S235JR(C)/1.0038(1.0122)4) | 235 | 360–510 | 24 | +20/27 | 0,35 | 5–100 | 5–303) |

| S235J0(C)/1.0114(1.0115) | 235 | 360–510 | 24 | 0/27 | 0,35 | 5–100 | 5–303) |

| S235J2(C)/1.0117(1.0119)4) | 235 | 360–510 | 24 | -20/27 | 0,35 | 5–100 | 5–303) |

| S275JR(C)/1.0044(1.0128)4) | 275 | 410–560 | 21 | +20/27 | 0,40 | 5–100 | 5–303) |

| S275J0(C)/1.0143(1.0140) | 275 | 410–560 | 21 | 0/27 | 0,40 | 5–100 | 5–303) |

| S275J2(C)/1.0145(1.0142)4) | 275 | 410–560 | 21 | -20/27 | 0,40 | 5–100 | 5–303) |

| S355JR(C)/1.0045(1.0551) | 355 | 470–630 | 20 | +20/27 | 0,45 | 5–100 | 5–303) |

| S355J0(C)/1.0553(1.0554) | 355 | 470–630 | 20 | 0/27 | 0,45 | 5–100 | 5–303) |

| S355J2(C)/1.0577(1.0579)4) | 355 | 470–630 | 20 | -20/27 | 0,45 | 5–100 | 5–303) |

| S355K2(C)/1.0596(1.0594)4) | 355 | 470–630 | 20 | -20/40 | 0,45 | 5–100 | 5–303) |

- Valid for thicknesses up to 30 mm, larger thicknesses according to the standard

- Valid for thicknesses up to 16 mm, larger thicknesses according to the standard

- According to the standard

- By agreement in accordance with AD2000–Merkblatt W1/W10

- Greater thicknesses up to 200 mm upon agreement

Realizations

Střížkov subway station in Prague, Czech Republic

It is a unique steel construction of the metro station roof, which consists of two 160m arches and the roof itself. Year of implementation: 2006.

Consumed material: approx. 1,000 tons of sheets.

BMW Exhibition Pavilion in Frankfurt am Main, Germany

The modern and timeless design carries elegance and clean lines. Its design corresponds with the exhibited new models of the successful car manufacturer. Year of implementation: 1999–2000.

Consumed material: approx. 100 tons of sheets.